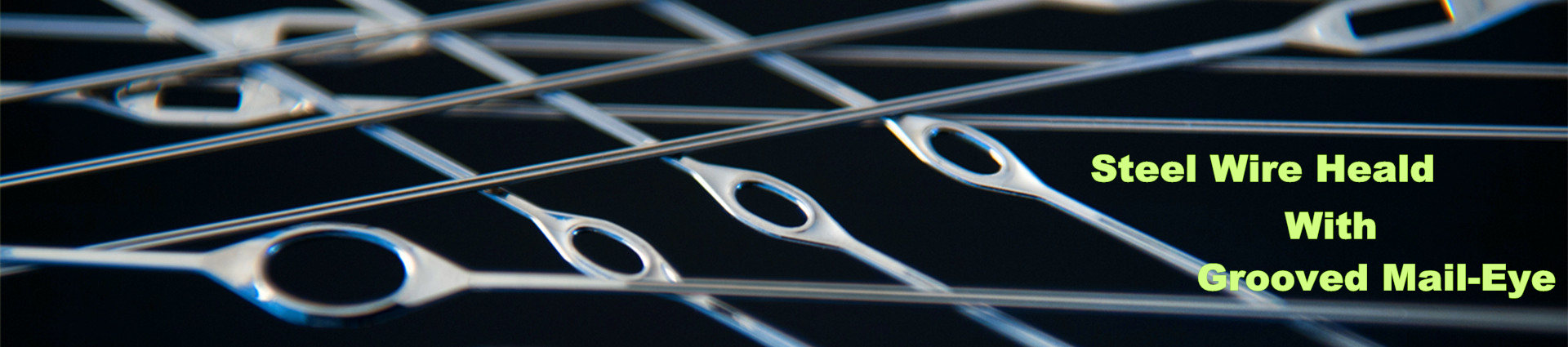

- Textile Accessories

- Shuttle Loom Parts

- Textile Equipment

- 1511 Textile Machine Parts

- 1515 Textile Machine Parts

- GA615 Shuttle Loom Parts

- Textile Hardware And Tools

- Weaving Machinery

- Textile Auxiliary Equipment

- Textile Picker and Buffer

- Textile Wooden Parts

Reasons For Abnormal Wear Of Loom Shuttle

This article focuses on introducing the reasons for abnormal wear of weaving machine shuttles, analyzing the causes of shuttle wear from four common aspects of the weaving structure. The text description is simple and clear, making it easy for textile maintenance workers to quickly identify the fault and promptly remove the shuttle wear fault.

The poor installation of the weft beating device on the shuttle weaving machine is an important reason for the severe abnormal wear of the shuttle, which is mainly manifested as:

1. Incorrect curvature of the shuttle board or reed arc can cause both abnormal flight of the loom shuttle and wear on the back and bottom of the shuttle.

2. When the front convex edge plate is lifted, the rear side is higher than the bottom plate of the shuttle box by more than 0.8mm. When changing the shuttle, the friction between the upper plane of the loom shuttle and the front brake rail increases, causing wear and affecting the positioning of the shuttle during shuttle changing.

3. The shuttle iron protrudes too much into the shuttle box, and the front and rear positions of the gantry stop and steel reed are improper. The angle of the steel reed and shuttle box back plate of the loom is not correct, causing wear on the shuttle.

4. The shuttle box components have burrs or damage, and the shuttle box spacing is too small, resulting in wear and tear of the loom shuttle.

Abnormal wear caused by other reasons includes:

I、 Reasons For Wear On The Front Surface Of The Shuttle:

1. The shuttle box is too tight (including the shuttle box being too narrow or the pressure of the shuttle iron springs K63 and K69 being too high).

2. The front protective plate of the shuttle box and the front brake rail themselves are bent, deformed, or have rough and uneven surfaces.

3. The front protective plate and front brake rail of the shuttle box are not at a 90 ° angle to the bottom plate of the shuttle box.

II、 Reasons For Wear On The Upper Front Corner Of The Shuttle

1. The push shuttle frame N2 extends short outside the front brake rail.

2. The tension of the weaving machine spring K56 is insufficient.

3. The lower edge of the blocking shuttle iron N24 has a burr, and the lower edge of the front brake rail has a burr.

4. The vertical surface of the front brake rail exceeds the vertical surfaces of the front tongue plate support feet K65 and K66.